Look, I’ve been in the sheet metal fabrication business long enough to know that one size doesn’t fit all when it comes to HVAC projects. That’s exactly why prototyping has become such a game-changer for contractors who refuse to settle for “good enough.” As someone who’s watched countless projects go sideways because of untested designs, I can tell you that smart prototyping saves both time and money—two things we never have enough of in this business.

At HVAC Metals LLC, we’ve been perfecting our prototyping process since 2015, and frankly, it’s transformed how we work with contractors across New Jersey, New York, and Pennsylvania. When you’re dealing with complex installations or custom solutions, there’s no substitute for getting your hands on a physical prototype before committing to full production.

Why HVAC Prototyping Makes or Breaks Your Project

Here’s what I’ve learned after years of working with contractors: the projects that run smoothest are the ones where we prototype first. It’s not just about avoiding mistakes—though that’s certainly part of it. Prototyping gives you the confidence to know that what you’re installing will work exactly as planned, fit perfectly, and perform reliably for years to come.

Last month, we had a facility manager from a major industrial complex in Newark who needed custom ductwork for a retrofit project. Instead of jumping straight into production, we created a prototype section that allowed him to test the airflow characteristics and verify the fit with existing infrastructure. That small investment in prototyping saved him from a potential $15,000 mistake when we discovered the original specifications wouldn’t work with the building’s unique structural constraints.

The Real Cost of Skipping Prototyping

I’ve seen too many contractors learn this lesson the hard way. Without prototyping, you’re essentially gambling on every custom fabrication order. Moreover, when problems surface during installation, you’re looking at delays, rework costs, and frustrated clients. These issues compound quickly, especially when you’re working with tight deadlines and even tighter budgets.

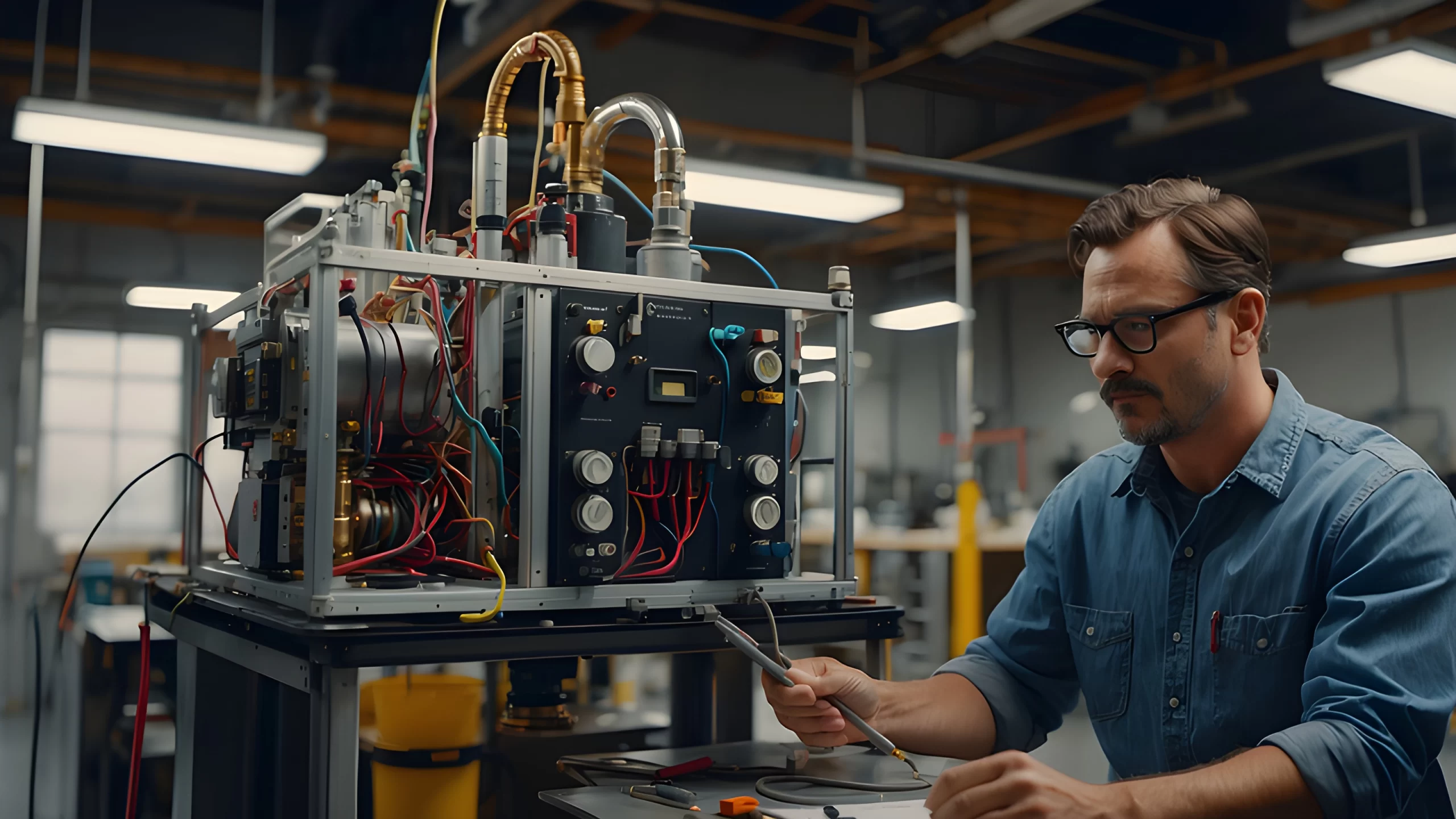

Advanced Prototyping Techniques for Custom HVAC Solutions

Our sheet metal fabrication process incorporates several prototyping methods that have proven invaluable for complex projects. We don’t just create one-off samples—we develop prototypes that serve as testing platforms for performance, fit, and manufacturability.

Rapid Prototyping for Time-Critical Projects

When speed matters, our rapid prototyping capabilities shine. Using advanced fabrication technology, we can produce functional prototypes within 24-48 hours. This approach has been particularly effective for emergency retrofits and fast-track construction projects where traditional lead times simply won’t work.

For example, we recently worked with a mechanical contractor on a hospital expansion project where the HVAC system needed to integrate with existing infrastructure without disrupting patient care areas. Through rapid prototyping, we tested three different connection methods and identified the optimal solution before the installation window opened. Consequently, the entire installation was completed over a single weekend with zero complications.

Collaborative Prototyping: Working with Engineers and Designers

One thing that sets us apart is how closely we work with designers and engineers during the prototyping phase. It’s not enough to simply fabricate what’s on the drawing—we need to understand the intent behind the design and identify potential improvements or issues before they become problems.

Our precision fabrication approach means we can accommodate design modifications quickly during the prototype phase. This flexibility has saved countless projects from costly redesigns and has strengthened our relationships with engineering firms throughout the tri-state area.

Material Testing Through Prototyping

Different projects demand different materials, and prototyping allows us to validate material choices under real-world conditions. We’ve tested everything from standard galvanized steel to specialized alloys, helping contractors make informed decisions about material specifications based on actual performance data rather than theoretical projections.

Recently, we prototyped ductwork sections using three different gauge materials for a large commercial project. The testing revealed that the middle option provided the optimal balance of cost, durability, and performance—information that wouldn’t have been available without hands-on prototyping.

Streamlined Prototyping Process for Busy Contractors

We understand that contractors need prototyping solutions that fit into their existing workflows without creating additional headaches. That’s why we’ve developed a streamlined process that delivers results without disrupting your project timeline.

Our prototyping service includes detailed documentation of test results, performance measurements, and recommendations for full-scale production. Additionally, we provide early morning delivery options—as early as 6 AM—so you can review prototypes before your crew arrives and make decisions without losing valuable installation time.

From Prototype to Production: Seamless Transitions

Once a prototype is approved, transitioning to full production is seamless. We maintain detailed records of all prototype specifications, ensuring that production pieces match exactly what was tested and approved. This consistency has earned us a reputation as one of the most reliable metal fabrication partners in the region.

The bottom line is this: prototyping isn’t just an extra step—it’s insurance for your project’s success. When you’re dealing with custom HVAC solutions, the small investment in prototyping pays dividends through reduced risk, improved performance, and the confidence that comes from knowing your system will work exactly as planned.

FAQs

How long does the prototyping process typically take?

Most prototypes are completed within 24-48 hours depending on complexity. For urgent projects, we can often deliver same-day prototypes using our rapid fabrication capabilities.

What’s the cost difference between prototyping and going straight to production?

While prototyping requires an upfront investment, it typically saves 15-30% on overall project costs by preventing costly mistakes, rework, and delays during installation.

Can you prototype modifications to existing ductwork systems?

Absolutely. We frequently create prototypes for retrofit applications, allowing contractors to test new components against existing infrastructure before committing to full modifications.

Written by: Arthur

HVAC Metals, LLC